top of page

FAQ

FAQ

Frequently asked questions

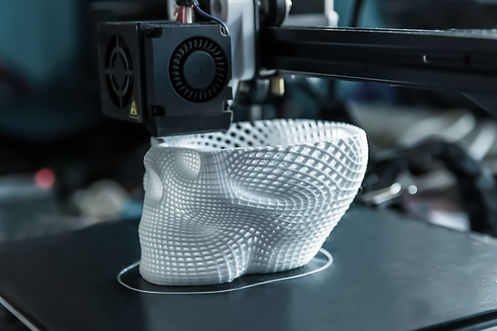

3D Printing

CNC

Laser Engraving

Whether you need a frame for your drone project, simply a door stopper or anything else in between, you can 3D print it. On the industrial side of things, 3D printing has enabled different industries, from the healthcare to the automotive industry, to do things never before possible and bring products to the market much faster. One spectacular area where 3D printing excels is in the medical area. Custom-built prostheses, 3D printed tissue are becoming more common in labs. But 3D printing also is strong when it comes to manufacturing small batches of goods. One example: the aerospace industries’ ability to 3D print small jet engine components with complex inner channeling, making the engine more fuel efficient. This would never have been possible with the traditional method of CNC milling

bottom of page